Flexographic Printing

U.S. production facilities most common as surface print on a paper substrates.

Flexography (often abbreviated to flexo) is a form of printing process which utilizes flexible relief plate. It is essentially a modern version of letterpress which can be used for printing on almost any type of substrate, including plastic, metallic films, cellophane, and most commonly paper. It is widely used for printing on the non-porous substrates required for various types of food. Platemaking The first method of plate development uses light-sensitive polymer. A film negative is placed over the plate, which is exposed to ultra-violet light. The polymer hardens where light passes through the film. The remaining polymer has the consistency of chewed gum. It is washed away in a tank of either water or solvent. The second method uses a computer-guided laser to etch the image onto the printing plate. Such a direct laser engraving process is called digital plate making.

Printing

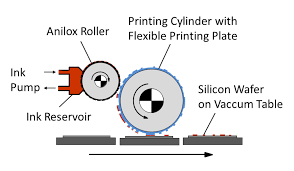

Printing Flexographic printing is made by creating a positive mirrored master of the required image as a3D relief in a rubber or polymer material. Flexographic plates can be created with analog and digital platemaking processes. The image areas are raised above the non- image areas on the rubber or polymer plate. The ink is transferred from the ink roll which is partially immersed in the ink tank. Then it transfers to theanilox or ceramic roll (or meter roll) whose texture holds a specific amount of ink

Since it is covered with thousands of small wells or cups that enable it to meter ink to the printing plate in a uniform thickness evenly and quickly (the number of cells per linear inch can vary according to the type of print job and the quality required). To avoid getting a final product with a smudgy or lumpy look, it must be ensured that the amount of ink on the printing plate is not excessive. This is achieved by using a scraper, called a doctor blade. The doctor blade removes excess ink from the anilox roller before inking the printing plate. The substrate is finally sandwiched between the plate and the impression cylinder to transfer the image. The sheet is then fed through a dryer, which allows the inks to dry before the surface is touched again.

Flexographic Printing Machine

Think flexographic printing is right for your business needs? Click here to get a Custom Quote or Request Samples!